New heat-sealable films: an ever increasing issue

The material used in the packaging lines is the heat-sealable film. Ensuring uniform welding is becoming more and more difficult with the introduction of new more complex films characterised by differentiated thicknesses or multilayer structures.

These materials are indeed extremely sensitive to temperature changes, thus requiring a more precise and efficient heating sytem.

The Company we worked with already used custom heaters with differentiated power with good results in terms of thermal uniformity. However, the materials’ increasing complexity asked for an even more advanced and efficient solution.

CREI solution

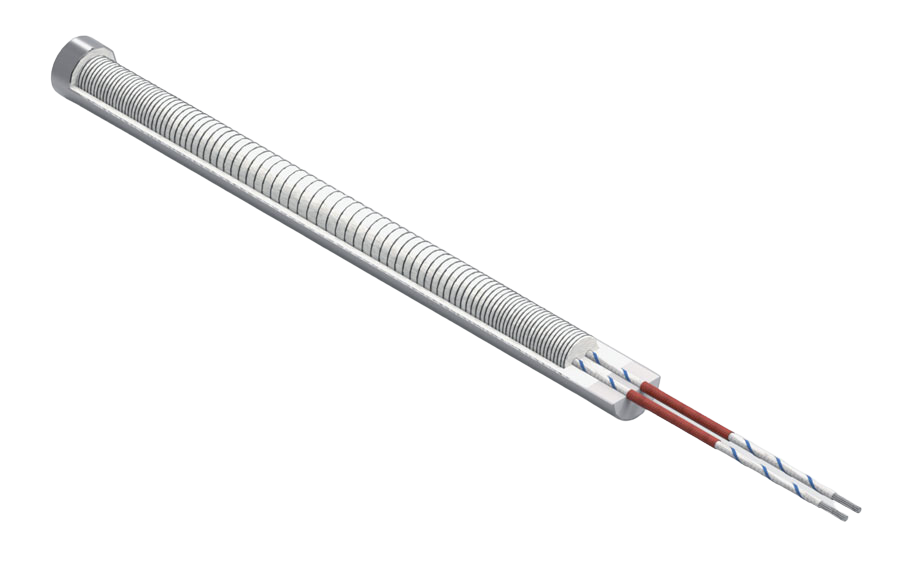

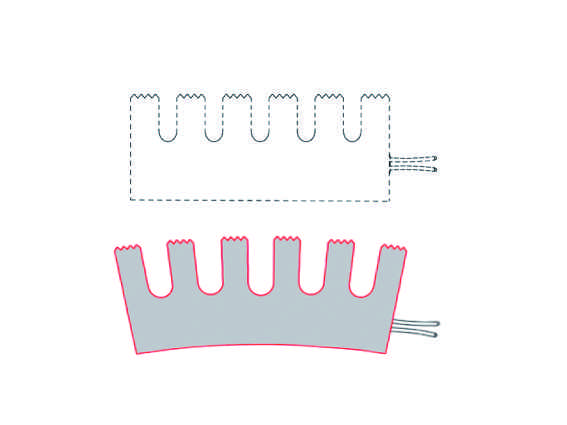

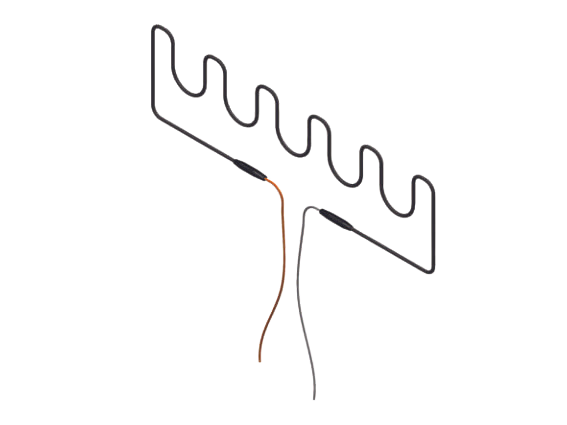

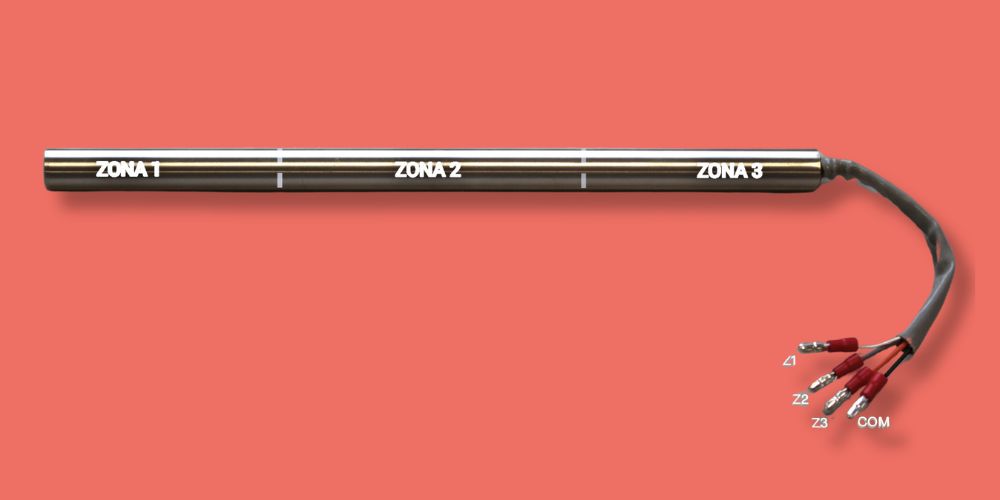

After analysing the problem and our customer’s requirements, we have developed a custom cartridge heater with multiple independent zones.

We have designed a heater divided into 3 separate zones , each one with an independent temperature control . These 3 zones can be powered separately following the different welding needs.

Besides the heater is coupled with PT-100 multi-zone temperature sensors with the aim of monitoring and adjusting the temperature with high accuracy.

Thanks to this innovation, the customer has been able to realize a higly innovative new line of plants , improving welding quality and production efficiency.

ADVANTAGES

Several benefits have been brought to the customer by this implemented solution:

- Increased temperature uniformity along the welding bar and no welding defects

- Independent control of the zones allowing for varying temperatures to be set according to need.

- Possibility of having unheated zones, useful for specific materials.

- Accurate temperature regulation, thanks to the PT100 multi-zone probes.